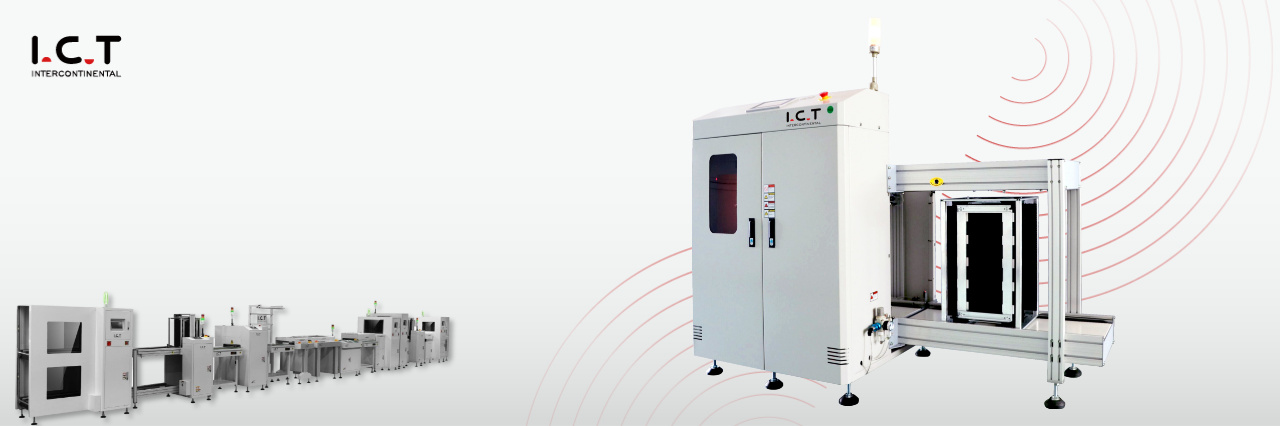

SMT PCB Loader Unloader

I.C.T

| Статус доступности: | |

|---|---|

| Количина: | |

| Advanced NG/OK SMT Unloader for Quality Lines

Smart SMT Ng/ok Unloader for Quality Management

The I.C.T SMT Ng/ok Unloader is the efficient PCB SMT Unloader machine that receives boards from AOI or SPI, reads the inspection signal, and stacks OK boards in one magazine while sending NG boards to another. Standard or full CE version—both have reinforced hardware, precise sensors, and flexible software. The SMT Ng/ok Unloader reduces rework time, enhances quality tracking, runs three shifts smoothly, and works as an Automatic Magazine PCB Loader SMT Ng/ok Unloader in your line.

| Detailed Product Features

The SMT Ng/ok Unloader uses thicker steel rails and base that comply with ISO and CE standards. It stays stable during constant use. Maintenance is quick and easy. The machine offers long-term reliability in high-volume factories.

Reliable Sensor Detection

High-quality sensors and bright lights provide clear OK/NG status. Buttons respond fast. The SMT Ng/ok Unloader detects inspection results accurately and keeps sorting steady without errors.

The system supports Industry 4.0 standards. Add IPC-CFX, Hermes, or other protocols when needed. Load new settings in under two minutes. The SMT Ng/ok Unloader connects to factory software and adjusts automatically.

Separate lowering units place OK and NG boards gently. The SMT Ng/ok Unloader fills two magazines without damage. Boards stay organized for rework or packing.

SMEMA interface is standard and ready. Optional smart links available. The SMT Ng/ok Unloader fits your line quickly and maintains steady flow during changeovers.

| Specification

| Model | DUL-M | DUL-L | DUL-LL | DUL-XL |

| Dimension(mm) | 1730*1530*1250 | 2065*1630*1250 | 2660*1760*1250 | 2660*1900*1250 |

| PCB Size(mm) | 50*50-330*250 | 50*50-445*330 | 50*50-530*390 | 50*50-530*460 |

| Rack Size(mm) | 355*320*563 | 460*400*563 | 535*460*563 | 535*530*563 |

| Control System | PLC | |||

| Power Supply | 1 PH AC 220V 50/60Hz (Option:110V to 380V) | |||

| Weight | 340 Kg | 380 Kg | 420 Kg | 460 kg |

| SMT Line Equipment List

Our turnkey High-Quality SMT Production Line delivers fully automatic, high-speed, and ultra-reliable PCBA manufacturing. The proven setup starts with the Vacuum and Magazine Loader, moves to a precision automatic printer for perfect solder paste application, continues with high-speed pick-and-place machines for accurate component placement, passes through a stable reflow oven for strong solder joints, and finishes with advanced AOI inspection to catch any defect. Every machine communicates seamlessly, reducing labor and boosting first-pass yield. This complete solution meets automotive, medical, consumer, and LED industry standards while keeping operating costs low and uptime extremely high.

| Product Name | Purpose in SMT Line |

|---|---|

| SMT Line | Turkey Fully Automated Traceable High-End SMT Line. |

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| Inspection Machine | SMT inspection devices like AOI, SPI, X-ray, and stencil inspecter. |

| Traceability Equipment | Records and tracks production data. |

| SMT Peripheral | Auxiliary SMT equipment like IC programmers, storage, X-ray counters, and tape splicers |

| PCB Cleaning Machine | Cleans PCB/Stencil to remove flux, dust, and contaminants post-soldering. |

| PCB Routing Machine | Precision-cuts PCBA outlines and slots with high-speed cutting. |

| SMT Bentop Robot | Automates screw-fastening and soldering for efficient SMT assembly. |

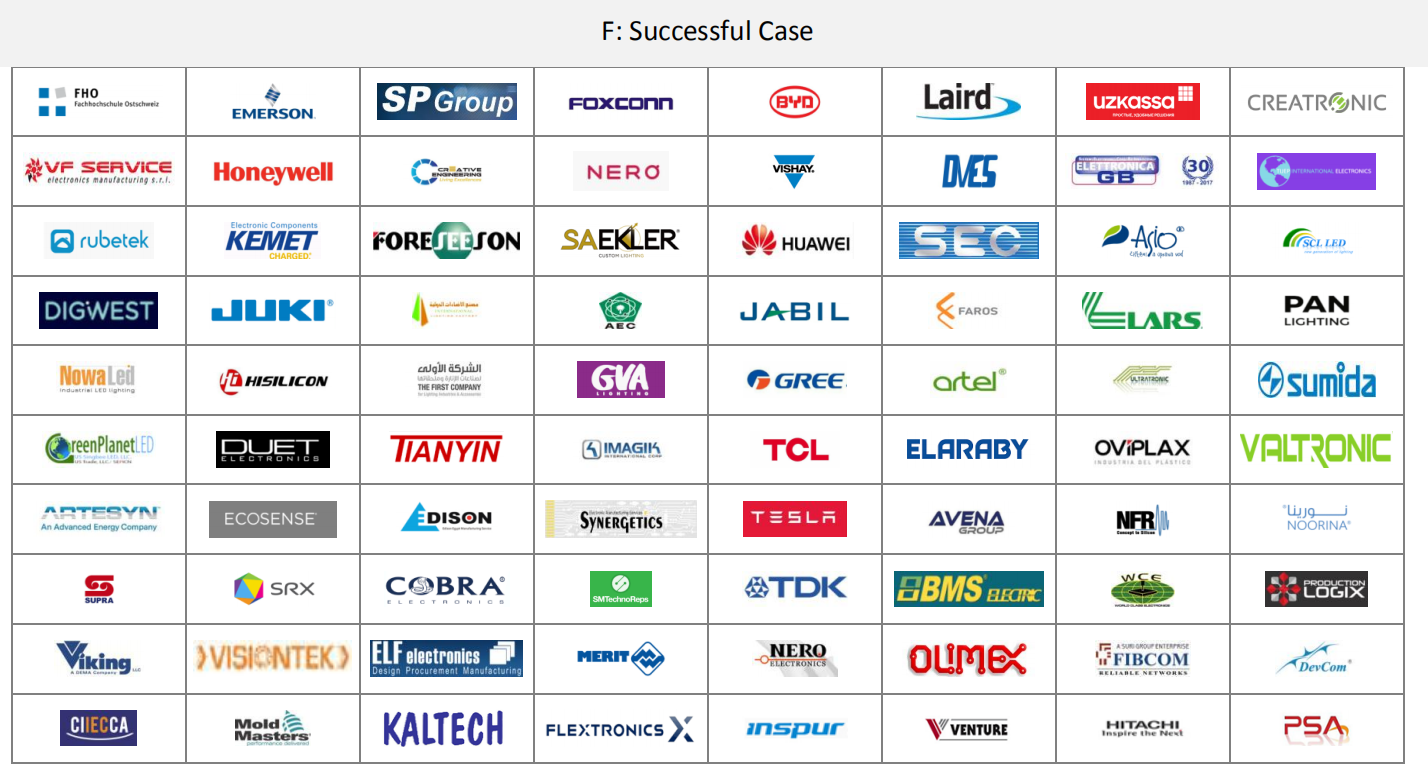

| Customer Success Story

In 2024 our engineers flew to Finland to install a complete LED panel production line for a leading European lighting manufacturer. The line included the SMT Ng/ok Unloader, 1.5 m automatic printer, SM482PLUS placement machine, L8 reflow oven, cooling buffers, linking conveyors, board splitter, and solder paste mixer. Our team completed installation, debugging, and operator training in only five days. The line reached full speed on the first production day with zero defects. The customer praised the accurate sorting of the SMT Ng/ok Unloader and perfect machine communication. They passed the strict European audit easily and ordered another line soon after.

| Professional Service and Training

In 2024 our engineers flew to Finland to install a complete LED panel production line for a leading European lighting manufacturer. The line included the SMT Ng/ok Unloader, 1.5 m automatic printer, SM482PLUS placement machine, L8 reflow oven, cooling buffers, linking conveyors, board splitter, and solder paste mixer. Our team completed installation, debugging, and operator training in only five days. The line reached full speed on the first production day with zero defects. The customer praised the accurate sorting of the SMT Ng/ok Unloader and perfect machine communication. They passed the strict European audit easily and ordered another line soon after.

| Похвала купаца

'Инжењери су брзо стигли и решили наш проблем истог дана.' 'НГ/ОК СМТ Унлоадер је стабилан и веома поуздан.' 'Паковање је било безбедно; машине су стигле савршене након испоруке.' 'Они брзо реагују и помажу нам да побољшамо контролу квалитета.'

| ИЦТ сертификати квалитета

Сваки НГ/ОК СМТ Унлоадер има ЦЕ, РоХС, ИСО9001 сертификате и више техничких патената. Свака машина пролази кроз стриктно тестирање пре испоруке како би се гарантовао врхунски квалитет и безбедност за купце широм света.

| Професионални добављач СМТ решења

Основан 2012. године, ИЦТ сада води модерну фабрику од 12.000 м⊃2; са скоро 90 запослених и сопственим Р&Д центром. Дизајнирамо, градимо и тестирамо све у нашој кући под строгим системима квалитета. Опслужујући преко 1.600 купаца у 72 земље, брзо смо расли тако што смо увек стављали успех купаца на прво место. Од једног усисивача и утоваривача магазина до комплетних линија по принципу „кључ у руке“, ИЦТ је дугогодишњи партнер фабрика којима се верују широм света.

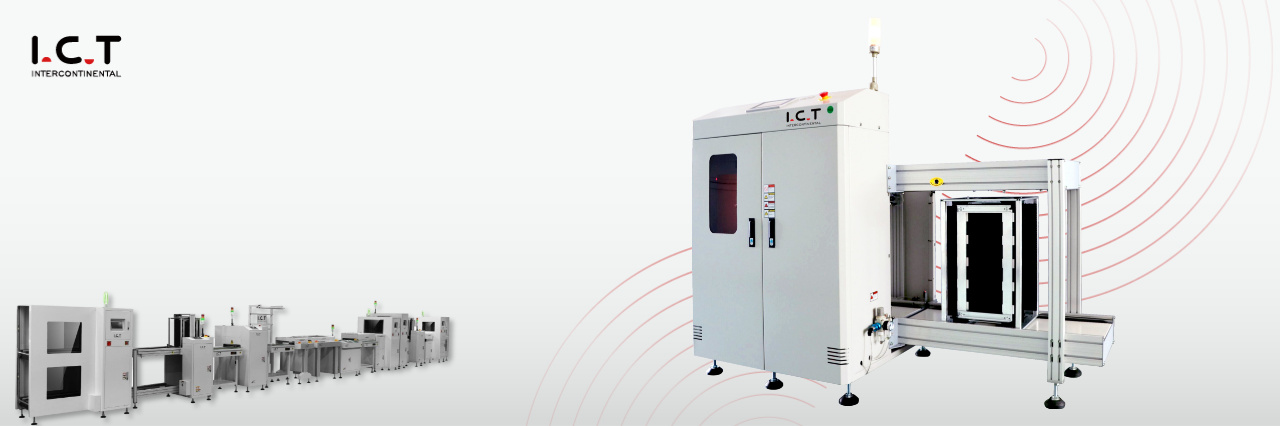

| Advanced NG/OK SMT Unloader for Quality Lines

Smart SMT Ng/ok Unloader for Quality Management

The I.C.T SMT Ng/ok Unloader is the efficient PCB SMT Unloader machine that receives boards from AOI or SPI, reads the inspection signal, and stacks OK boards in one magazine while sending NG boards to another. Standard or full CE version—both have reinforced hardware, precise sensors, and flexible software. The SMT Ng/ok Unloader reduces rework time, enhances quality tracking, runs three shifts smoothly, and works as an Automatic Magazine PCB Loader SMT Ng/ok Unloader in your line.

| Detailed Product Features

The SMT Ng/ok Unloader uses thicker steel rails and base that comply with ISO and CE standards. It stays stable during constant use. Maintenance is quick and easy. The machine offers long-term reliability in high-volume factories.

Reliable Sensor Detection

High-quality sensors and bright lights provide clear OK/NG status. Buttons respond fast. The SMT Ng/ok Unloader detects inspection results accurately and keeps sorting steady without errors.

The system supports Industry 4.0 standards. Add IPC-CFX, Hermes, or other protocols when needed. Load new settings in under two minutes. The SMT Ng/ok Unloader connects to factory software and adjusts automatically.

Separate lowering units place OK and NG boards gently. The SMT Ng/ok Unloader fills two magazines without damage. Boards stay organized for rework or packing.

SMEMA interface is standard and ready. Optional smart links available. The SMT Ng/ok Unloader fits your line quickly and maintains steady flow during changeovers.

| Specification

| Model | DUL-M | DUL-L | DUL-LL | DUL-XL |

| Dimension(mm) | 1730*1530*1250 | 2065*1630*1250 | 2660*1760*1250 | 2660*1900*1250 |

| PCB Size(mm) | 50*50-330*250 | 50*50-445*330 | 50*50-530*390 | 50*50-530*460 |

| Rack Size(mm) | 355*320*563 | 460*400*563 | 535*460*563 | 535*530*563 |

| Control System | PLC | |||

| Power Supply | 1 PH AC 220V 50/60Hz (Option:110V to 380V) | |||

| Weight | 340 Kg | 380 Kg | 420 Kg | 460 kg |

| SMT Line Equipment List

Our turnkey High-Quality SMT Production Line delivers fully automatic, high-speed, and ultra-reliable PCBA manufacturing. The proven setup starts with the Vacuum and Magazine Loader, moves to a precision automatic printer for perfect solder paste application, continues with high-speed pick-and-place machines for accurate component placement, passes through a stable reflow oven for strong solder joints, and finishes with advanced AOI inspection to catch any defect. Every machine communicates seamlessly, reducing labor and boosting first-pass yield. This complete solution meets automotive, medical, consumer, and LED industry standards while keeping operating costs low and uptime extremely high.

| Product Name | Purpose in SMT Line |

|---|---|

| SMT Line | Turkey Fully Automated Traceable High-End SMT Line. |

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| Inspection Machine | SMT inspection devices like AOI, SPI, X-ray, and stencil inspecter. |

| Traceability Equipment | Records and tracks production data. |

| SMT Peripheral | Auxiliary SMT equipment like IC programmers, storage, X-ray counters, and tape splicers |

| PCB Cleaning Machine | Cleans PCB/Stencil to remove flux, dust, and contaminants post-soldering. |

| PCB Routing Machine | Precision-cuts PCBA outlines and slots with high-speed cutting. |

| SMT Bentop Robot | Automates screw-fastening and soldering for efficient SMT assembly. |

| Customer Success Story

In 2024 our engineers flew to Finland to install a complete LED panel production line for a leading European lighting manufacturer. The line included the SMT Ng/ok Unloader, 1.5 m automatic printer, SM482PLUS placement machine, L8 reflow oven, cooling buffers, linking conveyors, board splitter, and solder paste mixer. Our team completed installation, debugging, and operator training in only five days. The line reached full speed on the first production day with zero defects. The customer praised the accurate sorting of the SMT Ng/ok Unloader and perfect machine communication. They passed the strict European audit easily and ordered another line soon after.

| Professional Service and Training

In 2024 our engineers flew to Finland to install a complete LED panel production line for a leading European lighting manufacturer. The line included the SMT Ng/ok Unloader, 1.5 m automatic printer, SM482PLUS placement machine, L8 reflow oven, cooling buffers, linking conveyors, board splitter, and solder paste mixer. Our team completed installation, debugging, and operator training in only five days. The line reached full speed on the first production day with zero defects. The customer praised the accurate sorting of the SMT Ng/ok Unloader and perfect machine communication. They passed the strict European audit easily and ordered another line soon after.

| Похвала купаца

'Инжењери су брзо стигли и решили наш проблем истог дана.' 'НГ/ОК СМТ Унлоадер је стабилан и веома поуздан.' 'Паковање је било безбедно; машине су стигле савршене након испоруке.' 'Они брзо реагују и помажу нам да побољшамо контролу квалитета.'

| ИЦТ сертификати квалитета

Сваки НГ/ОК СМТ Унлоадер има ЦЕ, РоХС, ИСО9001 сертификате и више техничких патената. Свака машина пролази кроз стриктно тестирање пре испоруке како би се гарантовао врхунски квалитет и безбедност за купце широм света.

| Професионални добављач СМТ решења

Основан 2012. године, ИЦТ сада води модерну фабрику од 12.000 м⊃2; са скоро 90 запослених и сопственим Р&Д центром. Дизајнирамо, градимо и тестирамо све у нашој кући под строгим системима квалитета. Опслужујући преко 1.600 купаца у 72 земље, брзо смо расли тако што смо увек стављали успех купаца на прво место. Од једног усисивача и утоваривача магазина до комплетних линија по принципу „кључ у руке“, ИЦТ је дугогодишњи партнер фабрика којима се верују широм света.

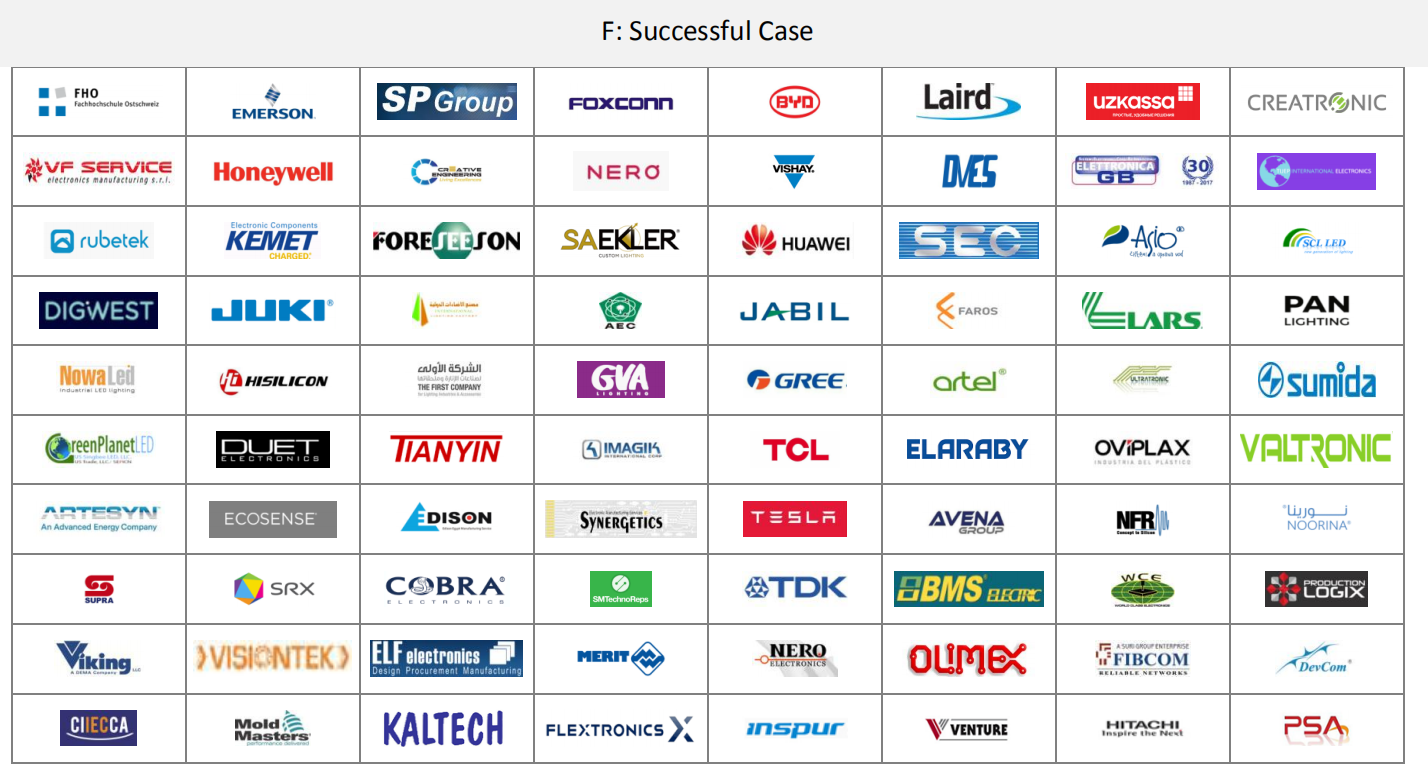

I.C.T - Our Company

About I.C.T:

I.C.T is a leading provider of factory planning solution. We have 3 wholly-owned factories, providing professional consultation and services for global customers. We have more than 22 years of eletronic overall solutions. We not only provide a complete set of equipment, but also provide full range of technical support and services, and give customers more reasonable professional advice. We help many customersv to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are trustworthy.

Exhibition

I.C.T - Our Company

About I.C.T:

I.C.T is a leading provider of factory planning solution. We have 3 wholly-owned factories, providing professional consultation and services for global customers. We have more than 22 years of eletronic overall solutions. We not only provide a complete set of equipment, but also provide full range of technical support and services, and give customers more reasonable professional advice. We help many customersv to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are trustworthy.

Exhibition

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

5. We Can Solve Any Question About SMT

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

5. We Can Solve Any Question About SMT